Lonza introduces new modular complex that offers flexibility and individually tailored solutions to biomanufacturing challenges.

Lonza introduces new modular complex that offers flexibility and individually tailored solutions to biomanufacturing challenges.

Recipharm set up a manufacturing line at its facility in Sweden using LIDD’s NanoZolid technology.

Manufacturing capacity will be increased by one third and approximately 300 new high-wage and highly-skilled jobs will be created at the Fremont site.

Industry collaboration group releases technology roadmap to address pressure on biopharmaceutical manufacturers to innovate biomanufacturing processes.

GSK plans to invest in several UK manufacturing sites and to close its Slough site in conjunction with the sale of the Horlicks brand manufactured in Slough.

The addition of 20,000 sq. ft. of manufacturing and office space increases Avecia’s Milford, Ma, oligonucleotide capacity to 3.0 mol.

Higher-flow peristaltic pumps from Watson-Marlow Fluid Technology Group are designed for upstream and downstream bioprocessing with single-use fluid path assemblies.

ABEC increases the maximum capacity of its Custom Single Run Bioreactors to 4000 L, doubling the industry standard.

The authors present a shift toward more integrated purification processes.

Perfusion processes can attractive for biologics drug manufacturing; however, obstacles remain.

Continuous processing of 100 g of monoclonal antibody in 24 hours has been demonstrated using lab-scale equipment.

Sartorius Stedim Biotech combined the company’s ambr 15 bioreactor system with the Nova BioProfile FLEX2 cell culture analyzer for laboratory experiments.

This article summarizes the approaches, challenges, and future perspectives for the characterization of N-glycans in biopharmaceutical products.

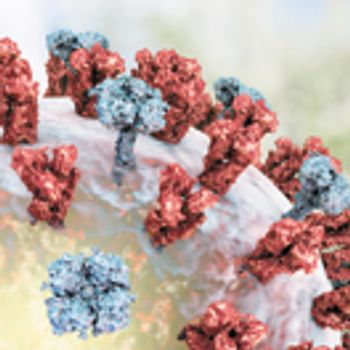

An increase in biologics raises awareness of particle generation and its role in negative patient outcomes.

Operated by BioOutsource, Sartorius’ subsidiary, the Glasgow, UK-based service center will offer physicochemical properties and structural attributes testing and allow clients to perform structural and functional analyses in parallel.

Can bioprocessing runs be consistently replicated in an inherently variable production environment?

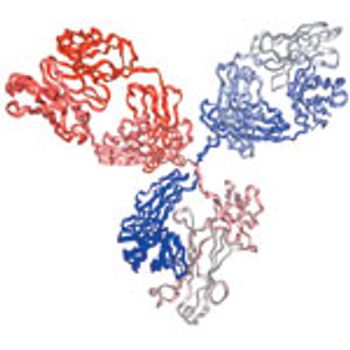

The unique structures of fusion proteins lead to expression, heterogeneity, and stability issues.

Improving the bioreactor growth environment increases the rigor of bioprocessing runs.

Chromatography modeling can enhance bioprocessing efficiencies.

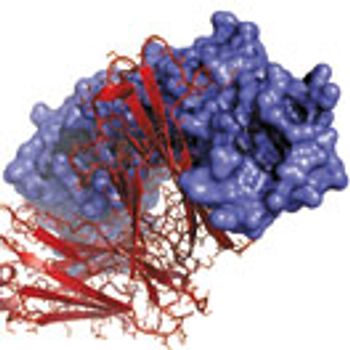

OrlaSURF technology can be used for the development of target-binding assays to monitor the binding of an ADC to its antigen.

The mAb is the first approved treatment that targets the progressive form of the disease.

Tony Pidgeon, process technology director at Patheon discusses challenges associated with and recent innovations in the fill/finish process for biopharmaceuticals.

The Basel office will house the clinical development team and other functions to progress the company’s lead compound emapalumab.

Richard D. Braatz, PhD, will discuss using mathematical models to design a continuous drug manufacturing plant and the differences between batch and continuous operations for biologics.

The process control and automation requirements of single-use systems differ from those of stainless-steel equipment.