Manufacturing Systems, Single-Use

Latest News

Latest Videos

More News

Gamma irradiation is being supplemented with alternative technologies.

Determining E&L risk from single-use components can be used to build the level of extractable profiling and PERLs.

Sterile filtration and use of sterile single-use materials provide the best solutions depending on vector size.

WMFTS’ new WMArchitect single-use solutions offers standard ready-to-use single-use assemblies as well as customized designs for biopharma fluid management.

Increases in efficiencies, flexibility, scalability, and sustainability are impacting adoption.

Despite a growing trend toward single-use bioreactors, stainless-steel retains its relevance for certain products.

The evolution of therapeutic modalities drives the adoption of single-use technologies.

SUS aids biopharma manufacturers to overcome the rigidity of more traditional stainless-steel technologies.

Pharmaceutical Technology Europe® spoke with Fiona Bellot, sales director, Cellexus BioreactorSystems, at the inaugural Start-Up Market on the show floor at CPHI Barcelona 2023.

Single-use technologies provide a barrier between operators and drug products, allowing for sterility and personnel safety in manufacturing.

Experts outline the benefits of single-use consumables relative to traditional approaches.

Although new single-use technologies offer the flexibility needed to overcome several challenges in ATMP production, there are many considerations and hurdles manufacturers must be aware of when scaling.

It is crucial to examine the context in which single-use waste is viewed.

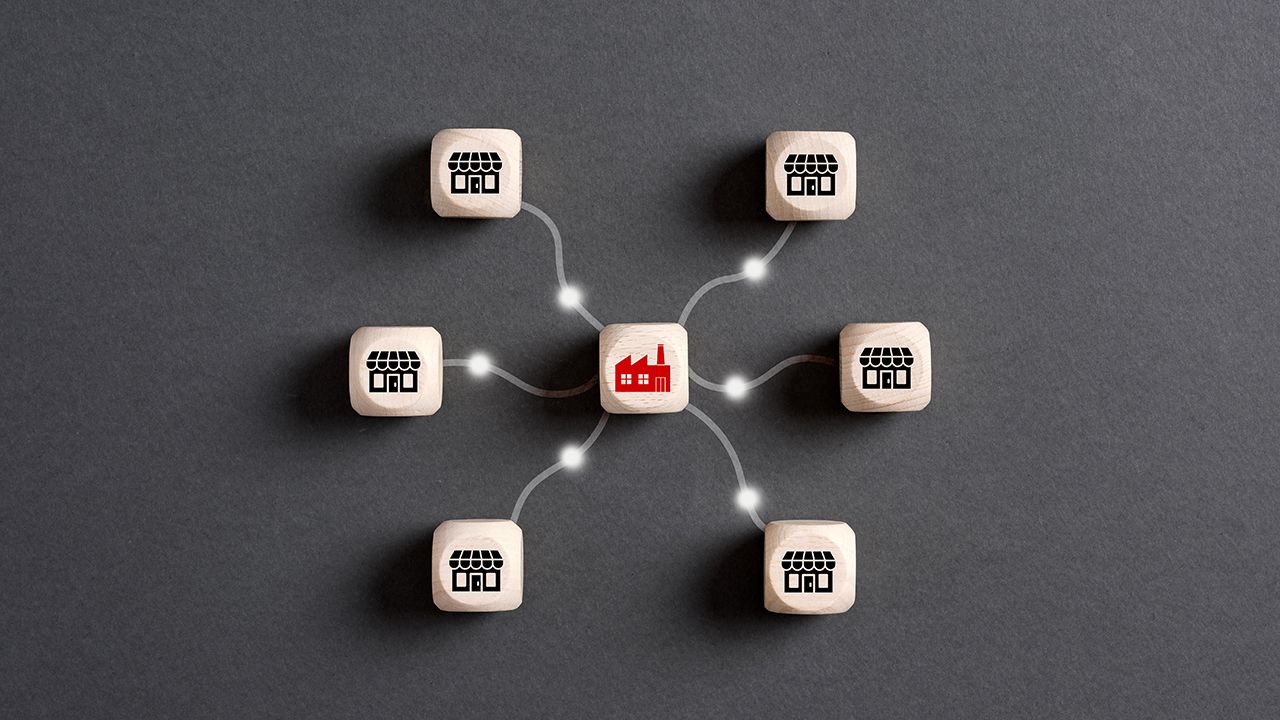

The combination of modular facilities and closed processing offers significant advantages in the production of biopharmaceuticals and is becoming a compelling option for manufacturing.

Single-use systems hold key benefits for biomanufacturers, despite certain limitations.

Digitalization of bioprocessing is slowly bringing benefits to the biopharma industry.

Through collaboration and transparency, engineering and automation companies can achieve great efficiencies and success for their customer by integrating intelligent design into a facility.

MilliporeSigma’s €130 million (USD$132 million) investment is designed to increase manufacturing capacity of single-use assemblies.

ChargePoint Technology has acquired single-use container company PuroVaso.

Specialty polymers demonstrate the advantages of single-use consumables in biopharmaceutical manufacturing.

An increasingly complex development pipeline and industry considerations, such as sustainability, are leading to a greater need for more efficient separation and purification in downstream processing.

Workforce training is crucial for biopharmaceutical manufacturing.

High Purity New England has launched its third facility, focused on single-use assemblies.

The past year of downstream processing has brought innovations in pH sensitive antibody purification, single-use fermentation separators, and more.

Flexible and efficient methods are needed for biopharmaceutical manufacturing.