The “next-generation” design for the pods will build on Pfizer’s existing modular prototype for oral solid-dose manufacturing.

The “next-generation” design for the pods will build on Pfizer’s existing modular prototype for oral solid-dose manufacturing.

ProBioGen plans to develop and scale-up production of a biosimilar to the mAb cancer drug trastuzumab and will transfer the commercial manufacturing process to Indonesia’s government-owned Bio Farma.

Biovest’s mAbVault provides supply-chain redundancy for antibodies that enables customers to lock in price-per-gram protein production.

Regeneron announced additional investments to its Limerick, Ireland biologics production facility.

Probiodrug has signed an agreement with Rentschler Biotechnologie GmbH for the development of PBD-C06, a pGlu-Abeta-specific monoclonal antibody, as treatment for patients with Alzheimer’s disease.

Rafe Swan/Getty Images; Dan WardIrreproducible preclinical research is a global, expensive, and well-recognized problem that contributes to delays a

Aragen Bioscience has licensed ProteoNic Biotechnology’s 2G UNic recombinant protein production technology, which increases manufacturing efficiency and reduces cost of goods for recombinant biologicals.

New single-use technologies and other filtration systems are beginning to address cost, throughput, and manufacturing footprint demands.

Biopharmaceutical company BeiGene plans to build facility in Suzhou to expand its clinical capability and prepare for commercial manufacturing.

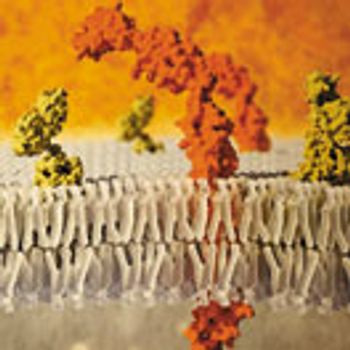

Licenses could potentially bring antibody R&D to areas beyond oncology, such as diabetes treatments

GEA's self-contained homogenizer is designed for laboratory applications, including cell dispersions.

A thorough cell-bank testing plan is necessary to certify the safety and purity of a resulting biopharmaceutical product.

The Mobius 2000-L single-use bioreactor from EMD Millipore offers configurable software, hardware, and single-use Flexware assemblies for suspension and adherent cell-culture applications.

Catalent licenses Excelimmune’s antibody combination therapy platform toenable the manufacture of multiple recombinant antibodies in a single batch culture.

Biogen plans to build a biologics manufacturing plant in northwest Switzerland using next-generation technologies to create efficiency and sustainability.

GSK will invest in an additional downstream isolation facility for amoxicillin production in Singapore.

Australian company, Genea Biocells, will open a facility in San Diego, California for cell and culture-media manufacturing and R&D.

IDT Biologika acquired Aeras' vaccine manufacturing facility, and the companies will work together on tuberculosis vaccine development.

Novasep's new antibody drug conjugate facility at its site in Le Mans, France will be commissioned in 2016.

Automation and disposables continue to reduce human error.

Contract service providers share insights on biopharma market developments and the implications of biosimilar drug approvals.

Medicago's new production facility will make plant-based vaccines and therapeutics.

Choosing the optimal protein expression vector depends on strain, promoter, and a number of other factors.

This article presents first-hand perspectives from industry users to suppliers of single-use sensors.