Process Control, Automation, and PAT

Latest News

Latest Videos

More News

Strategic AI integration in bio/pharma manufacturing enhances GxP compliance, quality, and operational efficiency through robust governance and risk management.

Leveraging computerized maintenance management systems software can enhance efficiency, improve quality control, ensure accurate documentation, and strengthen data integrity.

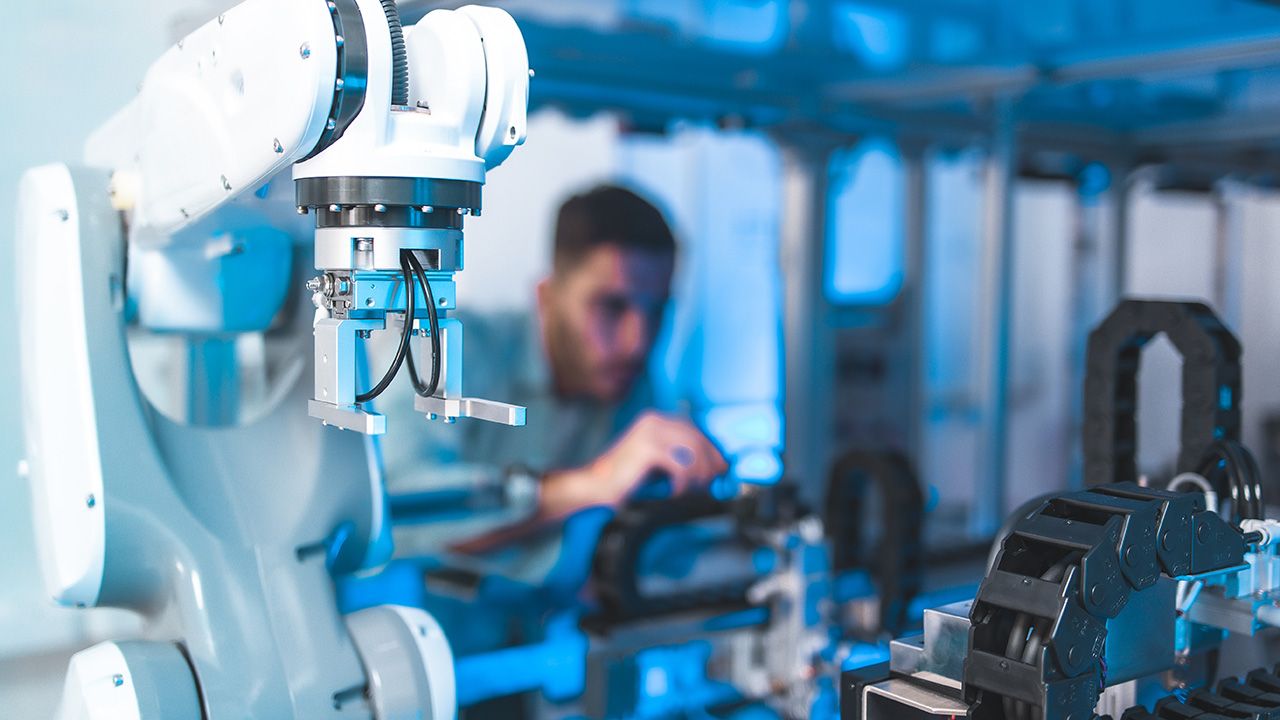

Advances in automation technologies and bioprocessing equipment are driving fuller adoption of automation in biomanufacturing.

RNA modalities will especially benefit from fuller adoption of continuous manufacturing platforms.

Under the expanded distribution service, Distek’s BIOne Benchtop Controllers will now be made available across the UK and Ireland.

UK Biocentre and Azenta Life Sciences Partner on Sample Storage Capabilities for Biomedical Research

UK Biocentre will now utilize Azenta Life Sciences’ automated storage system, which gives the center storage capacity for more than 35 million biosamples.

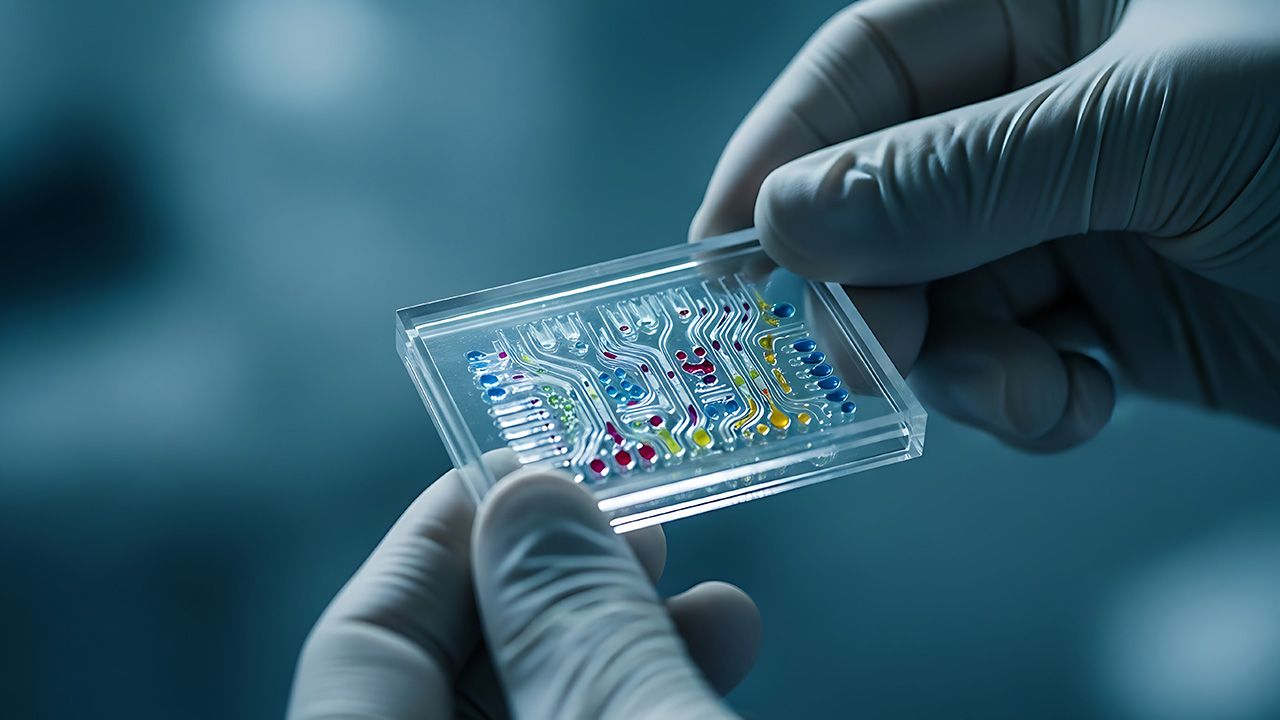

Under the partnership, the companies will combine fully automated and digitalized technologies aimed at reducing CGT manufacturing timelines to 2.5 days.

The collaboration will combine Cytiva’s CGT manufacturing technologies with Cellular Origins' robotic manufacturing platform.

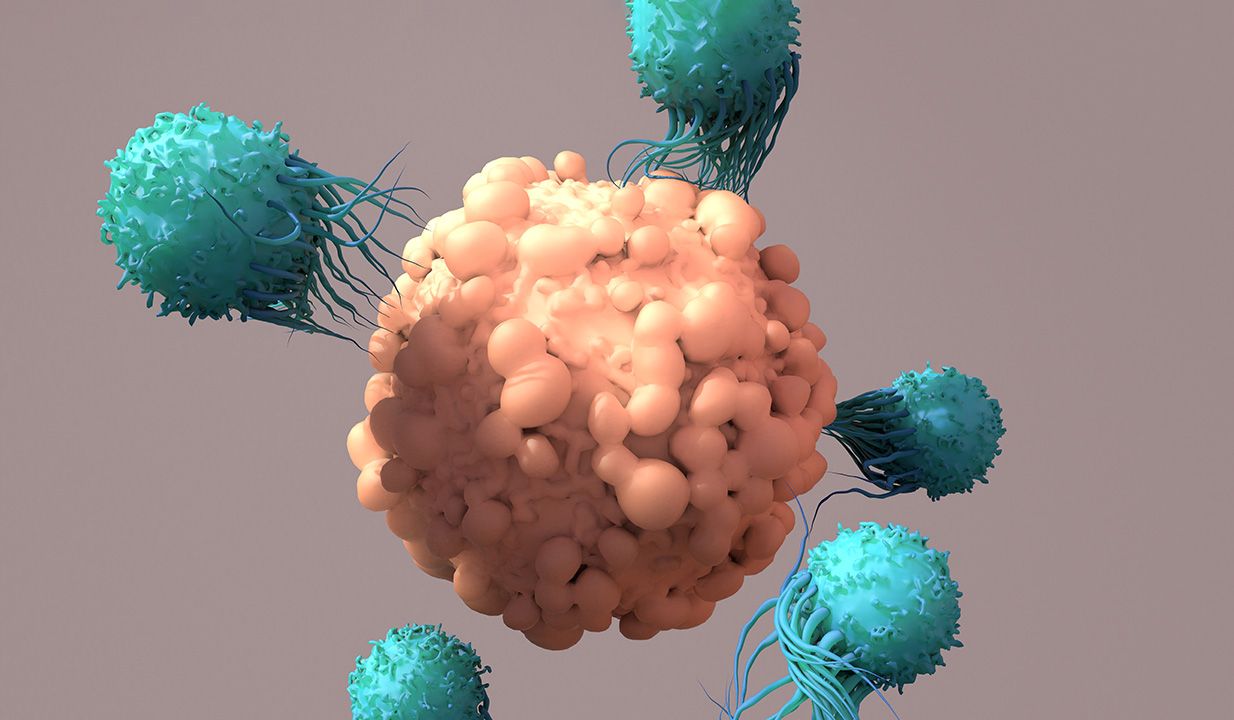

Lonza’s Synnafix has licensed its ADC technology to BigHat Biosciences, which will combine it with its ML design platform to generate newly designed ADCs.

The Novo Nordisk Foundation has committed DKK 600 million (US$87.4 million) towards the initial costs of the center housing the new supercomputer, which has the potential to accelerate drug discovery innovation.

Downstream processes may be streamlined by using automation.

Automation technologies used in the development and manufacture of biopharmaceuticals continue to evolve, providing the potential for reduced costs and time.

Technological advances are aiding manufacturers to streamline aseptic processes and improve time-to-market.

CGT manufacturing processes need automation as well as standardization, according to Lonza’s Joe Garrity and Jerry Jiang.

Improved efficiencies and reduced costs are clear advantages of automating drug manufacturing processes.

Cellular Origins will apply its robotic platform to establish automated CGT manufacturing at CGT Catapult’s manufacturing innovation center in Stevenage, UK.

Digital transformation is allowing for better handling, analysis, and protection of vast data collection.

Under the agreement, Bristol Myers Squibb will have access to Cellares’ fully automated cell therapy manufacturing platform, Cell Shuttle, to manufacture select CAR-T cell therapies.

NGS abbreviates drug discovery timelines.

SUS aids biopharma manufacturers to overcome the rigidity of more traditional stainless-steel technologies.

Cherwell Laboratories’ cleanroom microbiology solutions will join AnalytiChem’s group of seven companies across Europe, North America, and Australia.

This collaboration will combine BigHat Biosciences’ AI/ML-guided Milliner platform with AbbVie's expertise in oncology and neuroscience to develop next-generation antibodies.

MilliporeSigma’s new platform combines generative AI, machine learning, and computer-aided drug-design aimed at increasing the success rate of new drugs and therapies.

Digital transformation allows for smarter and connected biomanufacturing operations.

Under this multi-year collaboration, Genentech and NVIDIA will use AI to optimize and accelerate each company’s platforms to discover and develop innovative therapeutics.