Manufacturing

Latest News

Latest Videos

More News

Webinar Date/Time: Tue, Feb 24, 2026 11:00 AM EST

The SK bioscience–Gates MRI agreement highlights how scalable mAbs could broaden infant RSV prevention beyond high-income markets.

The facility builds on Eli Lilly's $50 Billion investment strategy to strengthen the company's domestic manufacturing capabilities.

The company’s major long-term capital commitment highlights how global drugmakers are anchoring future innovation, advanced modalities, and supply resilience within China’s life sciences ecosystem.

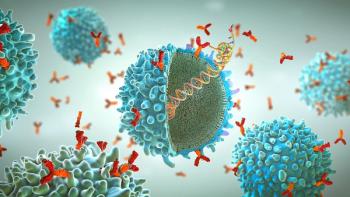

Cellares’ $257M Series D signals growing industry urgency to industrialize cell therapy manufacturing through automation and scalable production models.

The European Commission’s approval of GSK’s Arexvy for adults 18 years and older expands the respiratory syncytial virus vaccine market and signals broader adoption of adult immunization strategies.

Green chemistry is emerging as a strategic lever for biopharma manufacturing, enabling safer processes, efficiency gains, and long-term competitiveness.

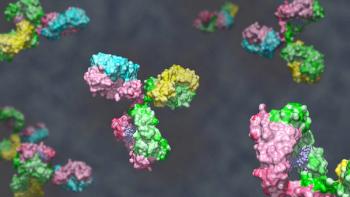

Next-gen antibody R&D is shifting to multifunctional modalities driven by manufacturing scale and regulatory acceleration.

Webinar Date/Time: Thu, Feb 12, 2026 11:00 AM EST

EU regulators clear Otsuka’s antisense injectable to prevent hereditary angioedema attacks, reinforcing momentum for RNA-based rare disease medicines.

Next-gen antibody R&D is shifting to multifunctional modalities driven by manufacturing scale and regulatory acceleration.

In 2026, AI and automation are anticipated to solve talent gaps and economic shifts to drive resilient drug discovery and manufacturing.

The partnership boosts BOT+BAL immunotherapy, securing US biologics manufacturing and accelerating Phase III mCRC development globally.

Johnson & Johnson reinforces its long-term domestic investment strategy with a new $2 billion biologics facility in Wilson, North Carolina, further elevating the state’s role as a global life sciences hub.

Single-use technologies provide efficiency and flexibility while reducing risk in the manufacture of cell and gene therapies.

The CDC has narrowed pediatric vaccine guidance, resetting evidence expectations and signaling potential shifts in vaccine uptake and market demand.

Biomanufacturing is shifting toward more resilient and digitized networks for enhanced supply security amid global and supply-chain volatility.

Key 2025 FDA draft and final guidances emphasize the modernization of biotech regulations, acceleration of rare-disease therapies, and streamlining of biosimilar pathways.

A look at interchangeable biosimilars gaining FDA approval, the growth in global partnerships, and the rising biologics patent cliff.

Samsung Biologics’ Maryland acquisition signals a major push into US biologics manufacturing, reshaping the company’s capacity strategy and supply chain resilience.

This past year in biologics was marked by clinical trends, manufacturing scalability, and regulatory acceleration for antibody therapeutics.

Norgine has gained regional rights to Vir Biotechnology’s hepatitis delta drug pairing, strengthening late-stage antiviral development across Europe, Australia, and New Zealand.

Fondazione and Orphan Therapeutics outline a US access model for Waskyra, highlighting new approaches to manufacturing, distribution, and sustainability.

Targeted integration enables predictable clonal cell lines, enhancing transgene control and accelerating biopharma cell line development.

Charles River has launched a second cohort to speed CGT innovation with technical guidance and scalable manufacturing support.