Industry experts discuss the challenges and regulations of setting up a CGMP-compliant stability testing program.

Industry experts discuss the challenges and regulations of setting up a CGMP-compliant stability testing program.

Providing regulators with a holistic approach to addressing deficiencies is the best response to an inspection, says Siegfried Schmitt, PhD, vice-president, technical, Parexel Consulting.

FDA sent a warning letter to NingBo Huize Commodity Co. after an investigation of the company’s Zhejiang facility found falsified quality documents.

FDA sent a warning letter to Emcure Pharmaceuticals, Ltd. because of sterility testing CGMP violations.

Spectrum Laboratory Products received an FDA warning letter after violations were found at its New Brunswick, NJ facility.

The agency is keeping Zolgensma on the market as it evaluates the accuracy of data submitted with the product’s biologics license application.

Quality risk management plans provide identified actions to ensure a continuous supply of safe and effective drug products, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished fellow, Regulatory Compliance Associates.

Strong personnel training, detailed SOPs, commitment to data integrity, investigation and implementation of appropriate modern methods, and employing Lean and Six Sigma methodology initiatives are key best practices for the quality control microbiology lab.

Too narrow a focus on regulatory compliance may prevent organizations from embracing-and profiting from-quality and operational excellence.

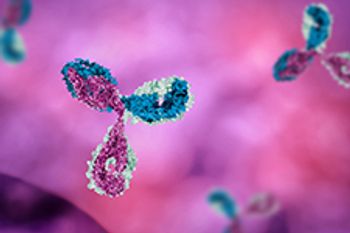

Protein characterization is a critical part of drug development, but as there are still limitations with available techniques, industry needs to look at technological advances to meet the specific requirements of complex molecule characterization.

The draft guidance describes how content should be organized in electronic submissions for all submission types under section 745A(a) of the FD&C Act.

FDA sent a warning letter to Ecometics, Inc. after the agency found CGMP violations at the company’s Norwalk facility.

Slovakia becomes the final European Union country to be recognized by FDA, and the mutual recognition agreement for inspections of manufacturing sites between the US and the EU is now fully implemented.

The FDA guidance defines changes to approved risk evaluation and mitigation strategies and clarifies submission guidelines.

The draft guidance provides industry with a guide for using the database to assist in the development of drug products.

FDA released draft guidance on using the USP pending monograph process in the drug application process.

Cultural and language discrepancies during an audit can be resolved using what many call a “playbook,” says Siegfried Schmitt, PhD, vice-president, technical, Parexel Consulting.

Using a QbD approach from early-stage development through commercialization can ensure that upstream processes are efficient and reliable.

Real-time monitoring of product- and process-related impurities remains a challenge.

Although downstream efficiency still lags behind upstream, engineering-driven innovation is breaking through boundaries.

Simple components help maintain physical integrity throughout a bioprocess setup, and single-use components play a role in ensuring a closed system for aseptic processing.

Single-use systems offer a solution to the challenges inherent in buffer preparation, which can be the cause of bottlenecking in bioprocessing.

Vida International received an FDA warning letter after an inspection found quality control violations.

The two countries have been included into the mutual recognition agreement between the European Union and the US FDA that recognizes facility inspections conducted in different territories.

Two facilities owned by Pharmasol Corporation were cited for violations of current good manufacturing practices in a FDA warning letter.