Investigating deviations or failures of combination products needs to accommodate both the drug and device components, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished

Investigating deviations or failures of combination products needs to accommodate both the drug and device components, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished

The agency sent a warning letter to Torrent Pharma after an inspection found violations of current good manufacturing practices that included a failure to thoroughly investigate batch failures.

In a statement, Janet Woodcock MD, director of FDA’s Center for Drug Evaluation and Research, highlighted the agency’s efforts to enhance the efficiency of postmarket drug safety surveillance.

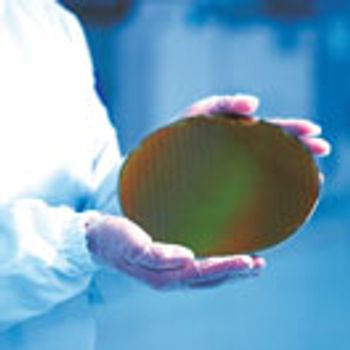

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

FDA readies more efficient oversight processes while advancing collaboration with Europe.

It is good industry practice to clarify the precise remit for each of the reviewers of a controlled document, says Siegfried Schmitt, PhD, vice-president, technical, Parexel Consulting.

Developing an effective bioassay is crucial for determining the potency of a drug substance or finished drug product. This article gives an overview of how to avoid most problems associated with correct bioassay development.

The guidance discuses waivers, refunds, and reductions of user fees under sections 735 and 736 of the FD&C Act.

Innoveix Pharmaceuticals, Inc. is voluntarily recalling all sterile compounded drug products due to a lack of assurance of sterility.

The guidance describes an optional streamlined submission process for use of an investigational in vitro diagnostic in a clinical trial for oncology therapies.

In an Oct. 10, 2019 press release, ChargePoint Technology announced that its smart monitoring system, Verifi, is now available for the biopharma market.

Falsified documents and manipulated test results prompt warnings and investigations.

Data supporting the quality and safety of product must meet the ALCOA+ elements in order to avoid regulatory citations for data integrity issues, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished fellow, Regulatory Compliance Associates.

The authors provide an introduction to aluminum adsorbed vaccines, review studies of antigen stability, and propose test methods for the analysis of aluminum vaccine release and stability analysis.

Software systems can help validate pharmaceutical manufacturing and steer the most appropriate design of processes in the right direction.

A guide for improving the planning and preparation of future validation work.

A new educational platform by Quality Executive Partners offers on-demand digital courses with technical content, virtual reality, and real-time coaching with an initial focus on sterile product manufacturing and microbiology.

The new program, Cornerstone, integrates process development expertise and novel technology to remove development bottlenecks in the manufacture of gene therapy medicinal products.

The authors take a closer look at these ongoing efforts to harmonize compendial standards, with perspective that may be helpful in considering the future direction of pharmacopoeias.

Pharmacopoeia harmonization provides better support for global regulatory agencies and addresses the global nature of bio/pharmaceutical manufacturing and supply.

This article examines the history and evolution of the pharmacopoeias and the particular challenges that must be overcome to achieve harmonization among the pharmacopoeias.

This article provides an end-to-end compendial framework to understand why compliance with pharmacopoeia standards is challenging.

This article provides the legal and regulatory basis for pharmacopoeia compliance and illustrates pharmacopoeia impact throughout the drug product lifecycle.

FDA issued a statement about the importance of reporting adverse events resulting from the use of compounded drugs.

FDA announced it is developing a series of guidance documents to promote methodological patient-focused drug development.