Manufacturers face the challenge of meeting growing demand for personalized biopharmaceuticals.

Manufacturers face the challenge of meeting growing demand for personalized biopharmaceuticals.

Use of a small-scale filler can result in increased filling efficiency.

The choice of expression system requires wise consideration of product complexities.

CPC presents a green alternative to chromatography that supports sustainable operations.

Experts outline the benefits of single-use consumables relative to traditional approaches.

The prestigious award, worth €20,000 (US$22,000), goes to Maurice Michel of the Science for Life Laboratory at Karolinska Institutet, Stockholm, Sweden.

The new headquarters located in Columbus, Ohio, more than triples Andelyn Biosciences’ footprint to meet growing demand for CGT services.

PIF has established Lifera, a new manufacturing entity that will manufacture, stockpile, and supply bio/pharmaceuticals both locally and through partnerships.

India’s Enzene Biosciences is investing $50 Million into a new biopharma manufacturing plant in Hopewell, NJ.

The new facility also provides a plan for scalable product production processes that can potentially be replicated by Vaxxas domestically and globally.

Mendus and NorthX Biologics will work to develop and commercialize Mendus’ lead asset, vididencel, an allogeneic dendritic cell vaccine.

Charles River’s off-the-shelf lentiviral vector packaging plasmids are intended for use with cell and gene therapies.

The new excipients manufacturing facility is expected to be completed in 2025.

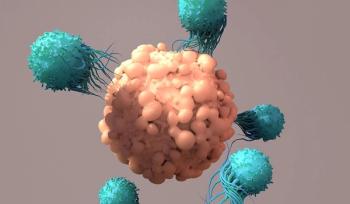

There are various challenges associated with the development of CAR-T therapies for solid tumor cancers.

Chris Spivey, editorial director, speaks with Sean Hart, CEO and SCO of LumaCyte, on percent transduction for AAV measured.

The collaboration between Samsung Biologics and Pfizer will focus on long-term biosimilars manufacturing.

Webinar Date/Time: Thu, Jul 27, 2023 11:00 AM EDT

invoX Pharma has made a second tranche of investment in pHion Therapeutics to support further development of next-generation mRNA vaccines.

New fields are being explored to bring novel antibody candidates to the pipeline.

Compliance with GMP standards remains an integral focus in bulk mAb manufacturing.

Scaling cell therapy production workflows requires the establishment of closed, automated steps.

WuXi Biologics is expanding its manufacturing capacity for drug substance and drug product at its sites in Leverkusen and Wuppertal, Germany.

Contract testing services demonstrate a major increase in the speed and efficiency of testing using new testing methods and technologies.

Third-party contract packaging service providers can help save time and money.

Vaccine nationalism strengthens viruses and poses deadly risks for all involved.