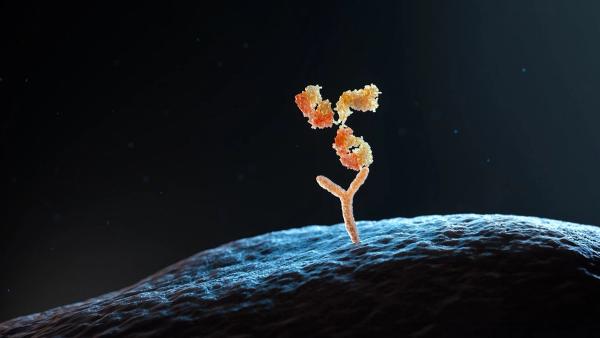

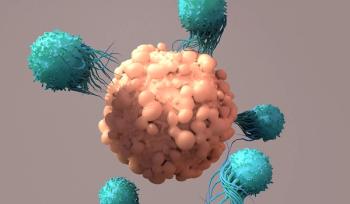

The new CGMP facility is expected to contribute to the development of mRNA therapeutics, with a building designed for the CGMP manufacture of mRNA-based in-vivo gene editing, gene-edited cell therapies, protein replacement therapies, cancer vaccines, and infectious disease vaccines.