ABEC, an equipment and engineering company, will provide a custom-made, single-use bioreactor to custom manufacturing firm, Emergent, for its Maryland manufacturing facility.

ABEC, an equipment and engineering company, will provide a custom-made, single-use bioreactor to custom manufacturing firm, Emergent, for its Maryland manufacturing facility.

The $72-million investment, part of a larger $850-million investment into its US operations, will allow the drugmaker to replace an outdated insulin vial-filling line and to upgrade technology at its Indianapolis manufacturing plant.

The partnership and the formation of the institute intend to bring together industry, academia, and regulators to tackle challenges and provide solutions for continuous manufacturing.

GE Healthcare opened a 3D printing lab in Sweden that will speed the launch of products for bio/pharma manufacturing, such as a custom chromatography column.

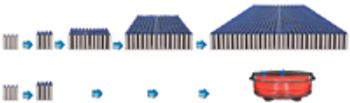

ABEC increases the maximum capacity of its Custom Single Run Bioreactors to 4000 L, doubling the industry standard.

Improving the bioreactor growth environment increases the rigor of bioprocessing runs.

Pump systems must be designed to meet the needs of specific processes, including preventing cross-contamination and damage due to shear forces.

A novel coiled flow inversion reactor (CFIR) improves process productivity and performance.

Model effectiveness is determined by the quality and composition of the data inputs.

Experts discuss recent advances in cell viability testing methods in bioreactors.

The authors present a case study in which four single-use vessels were fitted to an existing bioreactor system.

In semiconductor manufacturing, for example, a thorough understanding of process variation allows companies to manufacture circuits with billions of transistors at high yields. These variations are translated into a set of design rules, which help ensure that designs will be manufactured successfully and meet safety and other regulatory requirements.

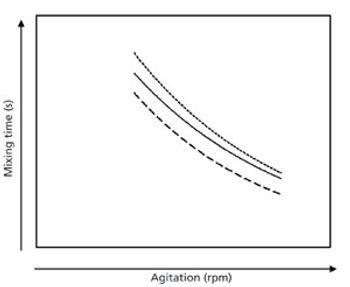

The authors conclude that miniature bioreactors can adequately predict the cell culture kinetics in scaled-up reactors using equal mixing times.

The Bothell, WA location will help the company reach its goal of expanding its global capacity by more than 30,000 liters.

Sartorius Stedim Biotech’s Sartoclear Dynamics is a clarification system designed to harvest mammalian cell cultures with high cell densities using single-use technology.

Meissner’s single-use biocontainer, FlexGro, is designed for use with rocker-style bioreactors.

This article presents first-hand perspectives from industry users to suppliers of single-use sensors.

Rentschler Biotechnologie launches 2000-L single-use bioreactor and announces additional expansion.

The new 2000-L bioreactor will double Rentschler’s single-use manufacturing capabilities.

As more biologic drugs come to market, manufacturers will require improved bioprocessing technologies.

The YSI Sitini Online Sampler draws fluids from a bioreactor and delivers the samples to an analyzer.

EMD Millipore and PharmaCell have entered into a collaboration to develop optimized large-scale expansion and harvest of HepaRG cells using bioreactor technology.

Project will optimize expansion and harvest of human cells in bioreactors.

The authors describe the growth characteristics of human mesenchymal stem cells cultured in a stirred-tank bioreactor.

A look at vaccine history, markets, manufacturing, and overcoming the scale-up dilemma.