The company showcased its compact robotic nest filling machine at CPhI Worldwide 2019 on Nov.–7 in Frankfurt, Germany.

The company showcased its compact robotic nest filling machine at CPhI Worldwide 2019 on Nov.–7 in Frankfurt, Germany.

The company introduced its new advanced elastomer, the 4040/40 formulation, and a new line extension of its AccelTRA component program, AccelTRA Select, at CPhI Worldwide from Nov. 5–7 in Frankfurt, Germany.

The plant in Singen, Germany will be used for formulation, filling, and packaging of Takeda’s vaccine candidate.

In batch production, efficient exception management means reducing the time required to identify, review, and resolve process exceptions. Incorporating review by exception functionality within manufacturing execution system (MES) software can streamline biopharmaceutical product release.

The companies plan to promote and manufacture Maverick, an emergency-use, cartridge-based auto-injector.

GE Healthcare Life Sciences will supply Akeso Pharmaceuticals with the FlexFactory platform to accelerate production of antibody drugs in the Guangzhou region.

Through the agreement, Samsung will provide flexible business terms while offering full regulatory support and improved batch release from small to large scale.

The company will invest $24 million into its Inchinnan, Scotland, site to expand global bioproduction capabilities with additional large-volume liquid manufacturing capacity for cell-culture media.

Schott will combine its adaptiQ platform with West’s Ready Pack system.

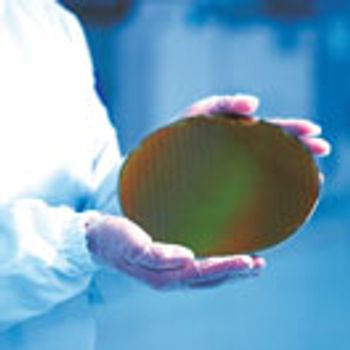

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

The project will seek to deliver treatments for the underlying cause of cystic fibrosis through submitted proposals from potential collaborators.

The authors of this study demonstrate an innovative method that is useful and complements traditional HA assays.

Limitations in traditional flu vaccine manufacturing methods underline the need for shifting to modern technologies.

Manufacturing differences between traditional mAb therapies and newer biotherapeutics dictate whether processes should be scaled up, scaled out, or use an alternate approach for commercial production.

The use of scale-down models allows for the theoretical optimization of processes and for troubleshooting problems during the developmental stage.

FDA report says drug shortages are underappreciated and patients pay a price.

Accelerated timelines and small batch volumes of cell and gene therapies pose unique challenges for product-release testing.

A recent report released by an FDA task force highlights the financial, manufacturing, and policy issues underlying the drug shortages of important prescription medicines in the United States.

GE Healthcare Life Sciences’ KUBio box is an integrated, flexible biomanufacturing environment for viral vector-based gene therapies.

US-based SP Industries acquired the sterile filling line assets of Spain-based i-Dositecno.

Gerresheimer enlarged a cleanroom, installed a high-performance furnace, and automated testing and packaging systems for pharmaceutical glass packaging in Essen, Germany.

The goal of the investment is for the cures to be made available across the globe, including in sub-Saharan Africa’s low-resource communities.

The partners have developed a scalable, cost-effective purification process for adeno-associated viruses.

Under the agreement, gene and cell therapy companies can go directly to Aldevron for NTC’s technology without acquiring a license from NTC.

The company will produce the anti-HER3 antibody drug HMBD-001for use within a clinical partnership between Cancer Research UK and Hummingbird Bioscience to test the agent in a Phase I trial.