The company’s next-generation ultraperformance liquid chromatography platform is designed to meet the evolving laboratory requirements for chromatographic performance.

The company’s next-generation ultraperformance liquid chromatography platform is designed to meet the evolving laboratory requirements for chromatographic performance.

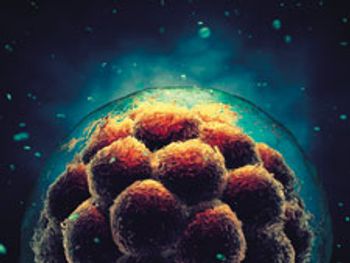

Higher cell titers and cell densities have posed a challenge to cell harvesting, a crucial step in biologics manufacturing.

More published data and initial regulatory approvals are needed to drive adoption of continuous bio-manufacturing.

Early adopters are benefiting from lower costs and increased productivity.

The new Acquity Arc Bio System by Waters is specifically engineered to enable efficient transfer and improvement of bioseparation analytical methods.

Advances in TFF and single-use systems help advance UF/DF on the continuous processing path.

The authors present a robust and easy-to-implement chromatography column performance assessment method, called direct transition analysis (DTA).

Single-use systems provide replaceable fluid paths.

The acquisition gives GE Healthcare access to a nanofiber-based platform purification technology that can offer improvements in biopharmaceutical productivity.

The company’s new modules offer scalable single-pass diafiltration and were exclusively showcased during its Leadership Forum series in Westborough, MA.

The companies have entered into a strategic collaboration to establish a new cell therapy and regenerative medicine manufacturing platform, which includes a new manufacturing facility in Belgium.

GE Healthcare opened a 3D printing lab in Sweden that will speed the launch of products for bio/pharma manufacturing, such as a custom chromatography column.

Process analytical testing for biopharmaceuticals requires enhanced methods due to complex bioprocesses.

This study outlines methods for an alternative protein-polishing process for challenging proteins.

A case study demonstrates that affinity chromatography can offer efficiency and scalability for gene therapy manufacturing using viral vectors.

Single-use and single-pass TFF devices are facilitating advances in biopharma manufacturing.

Sartorius Stedim Biotech expanded its range of single-use membrane chromatography solutions with Sartobind Cassettes.

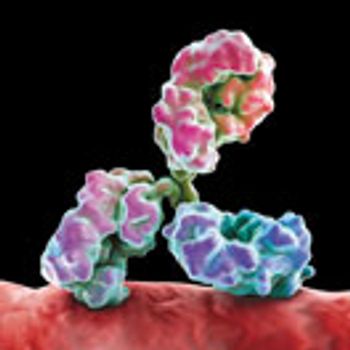

Increased understanding of potential impurities has spurred efforts to standardize monitoring procedures.

Can bioprocessing runs be consistently replicated in an inherently variable production environment?

The unique structures of fusion proteins lead to expression, heterogeneity, and stability issues.

Continuous downstream bioprocessing is proving its worth, but connecting different operations and integrating upstream remains a challenge.

For cellular materials, new ultra scale-down devices inform large-scale downstream processing techniques.

Chromatography modeling can enhance bioprocessing efficiencies.

The decision to use disposable bioreactors is now driven by commercial rather than technological considerations.

Although Protein A remains a top technology for monoclonal antibody purification, the industry continues to look for new approaches to improve conventional capture chromatography.