Achieving effective manufacturing processes and sufficient capacity remains a top priority across a diversified biologic drug pipeline.

Achieving effective manufacturing processes and sufficient capacity remains a top priority across a diversified biologic drug pipeline.

Temperature-sensitive biologics are lyophilized to preserve therapeutic viability, but the process presents complexities and challenges that are as yet not fully understood.

Industry experts debate the pros and cons of “going bigger” than the 2000-L industry norm in a single vessel.

Sartorius and the German Research Center for Artificial Intelligence have established a research laboratory for AI in the biopharmaceutical industry.

The acquisition expands Charles River’s scientific capabilities in cell therapy development.

Accelerated approval pathways and growing demand for cell and gene therapies are putting pressure on providers of cellular starting materials, and they must ensure a steady supply.

GE Healthcare Life Sciences will supply Akeso Pharmaceuticals with the FlexFactory platform to accelerate production of antibody drugs in the Guangzhou region.

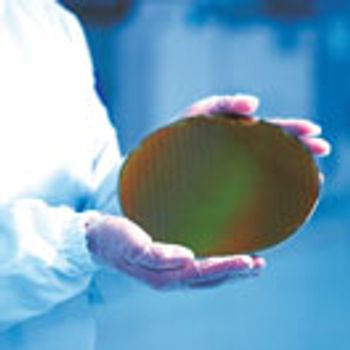

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

The authors of this study demonstrate an innovative method that is useful and complements traditional HA assays.

Limitations in traditional flu vaccine manufacturing methods underline the need for shifting to modern technologies.

Manufacturing differences between traditional mAb therapies and newer biotherapeutics dictate whether processes should be scaled up, scaled out, or use an alternate approach for commercial production.

The use of scale-down models allows for the theoretical optimization of processes and for troubleshooting problems during the developmental stage.

Accelerated timelines and small batch volumes of cell and gene therapies pose unique challenges for product-release testing.

GE Healthcare Life Sciences’ KUBio box is an integrated, flexible biomanufacturing environment for viral vector-based gene therapies.

The partners have developed a scalable, cost-effective purification process for adeno-associated viruses.

Ireland's National Institute of Bioprocessing Research and Training (NIBRT), together with technology providers such as GE Healthcare, and universities in Ireland and around the world, are developing courses that aim to close the gap between theoretical studies and practical workplace needs.

The new location is one of the world’s first digital facilities to use intensified, continuous biologics production technology.

Lonza, through its Ibex Solutions, will now cover preclinical and clinical development and manufacturing for a significant portion of Genmab’s pipeline.

Used with perfusion, alternating tangential flow and tangential flow filtration are redefining upstream efficiency.

Cloudleaf's Digital Visibility Platform can track which track location and additional environmental information, such as temperature, vibration, and shock, of sensors placed on raw material containers.

GSK’s expanded R&D and manufacturing facility in Upper Merion, PA houses a new analytical lab and flexible manufacturing equipment, including single-use bioreactors.

The new program, Cornerstone, integrates process development expertise and novel technology to remove development bottlenecks in the manufacture of gene therapy medicinal products.

FDA approved the drug after a successful open-label study of children aged six to 11 years and living with the condition.

The company’s Custom Single Run product line now has available bioreactors with working volumes of up to 6000 L.

Bayer will use ProBioGen’s GlymaxX technology to maximize the potency of its antibody drug candidate in development for oncological indications.