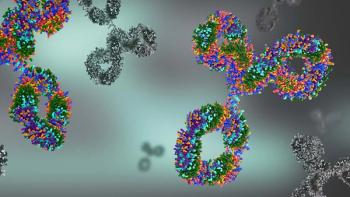

Further development of nucleic acid-based therapeutics has been accelerated by the recent success of mRNA vaccines.

Further development of nucleic acid-based therapeutics has been accelerated by the recent success of mRNA vaccines.

Complex hurdles complicate the development of emerging therapies.

Plant-based manufacturing technology gains mainstream edge in biopharmaceutical production.

Catalent will invest $350 million into integrated biologics drug substance and drug product manufacturing at Bloomington, Indiana facility.

The recent success of mRNA vaccines has opened the door for further and future development of nucleic acid-based therapies.

Spectrum Chemical has further expanded its bioCERTIFIED product portfolio to support the growing global demand for new vaccines and therapeutics.

The use of bioengineering offers practical tools for the evolution of host cells.

Capacity concerns and regulatory compliance considerations will drive the decision about outsourcing the manufacture of clinical trial materials.

Recipharm has strengthened its biologics manufacturing capabilities with the acquisition of both Vibalogics and Arranta Bio.

Thermo Fisher Scientific is expanding its Millersburg, Penn., site with a $40 million investment to support increased production of single-use technology for critical vaccines and biologics.

ImmunoGen and Eli Lilly and Company have entered into an agreement that gives Lilly exclusive rights to research, develop, and commercialize ADCs designed for targets selected by Lilly from ImmunoGen’s camptothecin technology.

Piramal Pharma Solutions plans to construct a multipurpose ADC manufacturing and aseptic fill/finish facility in Grangemouth, Scotland, and to upgrades its existing API manufacturing facility in Morpeth, England.

The need for specialized skills in biopharmaceutical manufacturing requires workforce training.

The growing use of automation and digitalization technologies push cell culture bioprocessing forward.

The need for sustainability and early considerations of a lyophilization strategy grow more pertinent on the back of growing biologics volume.

Build into the chemistry, manufacturing, and control strategy the ability to pivot and be flexible should the course change.

Arranta Bio will use Cytiva’s FlexFactory single-use manufacturing platform to produce mRNA vaccines.

Recipharm will build up its biologics service offering with the acquisition of GenIbet.

With this investment into Yapan Bio, Piramal Pharma adds new technologies and capabilities in large molecules, including vaccines and gene therapies, to its global offering.

Modeling techniques can improve process control and monitoring in biopharmaceutical production.

Upstream processing is better optimized with the help of automated workflows.

Enhancement of resin technology can improve the ability of chromatography to purify the growing landscape of increasingly complex biomolecules.

New and emerging biotherapeutic molecules drive the need for innovative solutions to meet cold-chain requirements.

Sanofi’s acquisition will grant access to Amunix's promising immuno-oncology pipeline.

FUJIFILM Diosynth Biotechnologies plans to invest £400 million (US$528 million) to expand its Billingham, Teeside facility in the United Kingdom.