The authors present a robust and easy-to-implement chromatography column performance assessment method, called direct transition analysis (DTA).

The authors present a robust and easy-to-implement chromatography column performance assessment method, called direct transition analysis (DTA).

MilliporeSigma will collaborate with IPS and G-CON to offer end-to-end, turnkey, modular MAb manufacturing.

Single-use systems provide replaceable fluid paths.

The company’s new modules offer scalable single-pass diafiltration and were exclusively showcased during its Leadership Forum series in Westborough, MA.

Connectors are a critical element in the process optimization of single-use bioprocessing systems.

The use of external retainers to enhance the seal between connectors and tubing is an essential component in single-use manufacturing systems.

ABEC, an equipment and engineering company, will provide a custom-made, single-use bioreactor to custom manufacturing firm, Emergent, for its Maryland manufacturing facility.

The $72-million investment, part of a larger $850-million investment into its US operations, will allow the drugmaker to replace an outdated insulin vial-filling line and to upgrade technology at its Indianapolis manufacturing plant.

This study outlines methods for an alternative protein-polishing process for challenging proteins.

The success of a truly integrated continuous processing platform relies on the collaborative efforts of upstream and downstream specialists.

Continuous downstream bioprocessing is proving its worth, but connecting different operations and integrating upstream remains a challenge.

Pump systems must be designed to meet the needs of specific processes, including preventing cross-contamination and damage due to shear forces.

Industry experts discuss best practices for selecting a separation technology.

Irvine Scientific’s new product range includes chemically-defined, serum-free media, to increase productivity of viral vectors and recombinant proteins in suspension cultures.

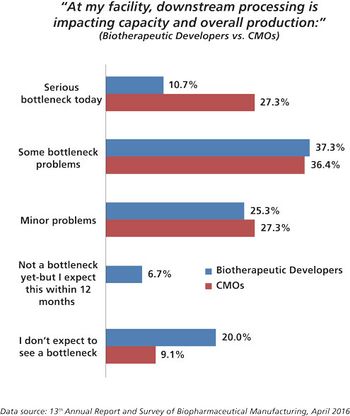

CMOs are working hard to improve performance by investigating new technologies for filtration and purification.

The company announced the launch of its first-in-class Lynx CDR connectors at INTERPHEX 2016.

Industry experts provide insights on the challenges and importance of using buffers in downstream processing.

The authors explore the use of precipitation using polyvinyl sulfonic acid and zinc chloride in place of capture chromatography to reduce the cost of goods in the insulin manufacturing process.

mstay/Getty ImagesBiopharmaceutical manufacturing involves a series of complex unit operations linked together to provide high-purity, biologic actives with specifi

BioPharm International sat down with Kevin Isett, PhD, co-founder and CEO of Avitide, to find out why he thinks the company’s tailored approach to purification resins will change the face of biopharmaceutical separation.

A new consortium involving Arecor, FUJIFILM Diosynth Biotechnologies and the Center for Process Innovation will focus on formulation innovation as a way to improve downstream processing and reduce biopharmaceutical cost.

Industry experts discuss the development of process chromatography in bioprocessing.

The company’s purification platform is thought to reduce the number of purification steps that are currently required for the manufacture of complex therapeutics.

The use of single-use systems in downstream processing offers benefits in filtration and sampling and may reduce the risk of contamination.

Sartorius Stedim Biotech’s Sartoclear Dynamics is a clarification system designed to harvest mammalian cell cultures with high cell densities using single-use technology.