The authors describe the impact of the knocking of the pgi gene of the wild type MG1655 strain on the growth kinetics of plasmid-free and plasmid-bearing cells.

The authors describe the impact of the knocking of the pgi gene of the wild type MG1655 strain on the growth kinetics of plasmid-free and plasmid-bearing cells.

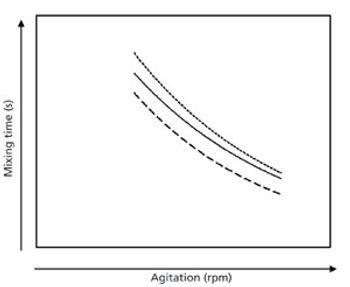

The authors conclude that miniature bioreactors can adequately predict the cell culture kinetics in scaled-up reactors using equal mixing times.

Use of a subspace model is a viable method to characterize process space variables and optimize process performance.

Growing differentiated cells from stem cells may now be a bit easier than before, thanks to the findings from a new study on the production of liver cells. The study, backed by the Centre for Regenerative Medicine and published in Stem Cell Reports, finds that laminins may be a crucial element for the successful clinical-scale production and culture of stem cell therapies. The UK Regenerative Medicine Platform, the European Union Seventh Framework Programme, and the German Federal Ministry of Education and Research funded the research.

The authors present a review of the techniques commonly used for glycosylation analysis.

Rafe Swan/Getty Images; Dan WardIrreproducible preclinical research is a global, expensive, and well-recognized problem that contributes to delays a

Biogen plans to build a biologics manufacturing plant in northwest Switzerland using next-generation technologies to create efficiency and sustainability.

EMD Millipore debuts a new cell-culture media compacting technology that will turn messy, dry powders into granules.

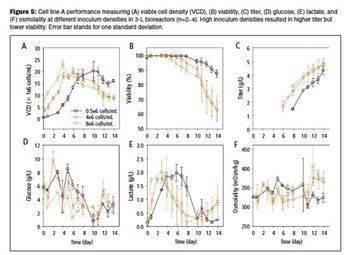

The use of commercially available media to achieve high titer in early process development is discussed.

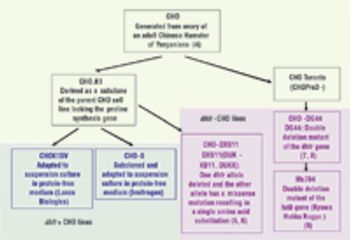

Catalent announced that it would partner with Mitsubishi Gas Chemical Company, and its subsidiary MGC Pharma, to promote GPEx technology, a high-titer vector for stable mammalian cell lines.

WuXi PharmaTech has completed a cell culture capacity expansion, including two 2000 L disposable bioreactors.

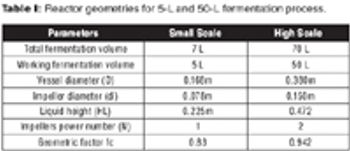

The authors present scale-up from a 5-L fermentor to a 50-L pilot-scale using the criterion of constant power consumption per unit liquid volume.

The authors describe challenges faced in transfer and scale-up of a fermentation process.

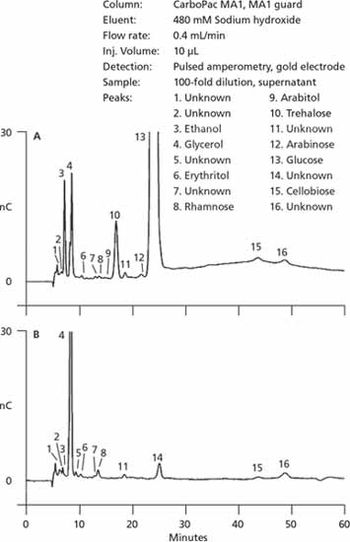

An overview of applications in the analysis of nutrients and metabolites.

A hollow fiber matrix allows for efficient harvest of secreted proteins.

The authors examine several issues that will help streamline negotiations between a service provider and a cell-culture medium consumer.

The authors present lessons learned from a case study of the transfer of a cell culture biotherapeutic process to a CMO.

Rolling-tube system balances scale-up accuracy and thoroughput.

Computational fluid dynamics can resolve performance problems.

Computational fluid dynamics is a powerful tool to optimize processes.

How to reduce plasmid-mediated metabolic burden for higher yields.

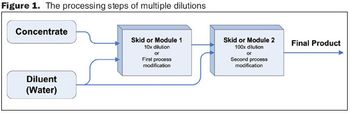

Automated in-line dilution can help solve capacity, financial, and quality concerns that biopharmaceutical manufacturing plants may be facing.

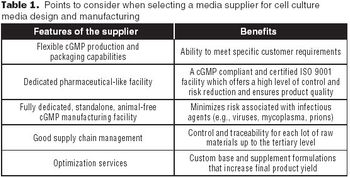

To select the right partner for media design and optimization services, several key factors must be considered.

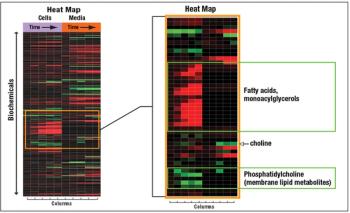

Through metabolomics, the metabolic underpinnings of cellular changes can be rapidly pinpointed, directing process development scientists to key areas for cell culture optimization.