Bio/Pharma companies are galvanized to develop COVID-19 therapies under FDA’s acceleration program.

Feliza Mirasol is the science editor for BioPharm International.

Bio/Pharma companies are galvanized to develop COVID-19 therapies under FDA’s acceleration program.

Recent industry guidance aims to anchor rapid COVID-19 vaccine development in good manufacturing practice protocols.

Automation, digitalization, and supply-chain strategies help mitigate vulnerabilities in both autologous and allogeneic cell therapy manufacturing.

An innovation such as synthetic biology can develop a consistently stable starting cell line for cell therapy source material.

Fill/finish inspection for vaccine vials and syringes must remain GMP-compliant while aiming for fast, efficient methods.

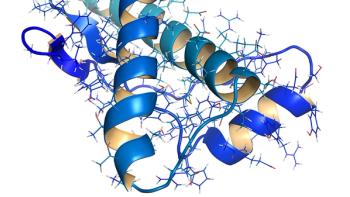

Glycoengineering is growing in importance as a technique to improve antibody therapeutic efficacy, safety, and product quality.

As technology matures, inefficiencies and process limitations in downstream process chromatography are improved.

Current and newer biologic modalities pose increasingly complex challenges to the detection and characterization of protein aggregates.

Process modeling offers an opportunity to troubleshoot for and anticipate difficult aspects of a bioprocess.

Glycoengineering is growing in importance as a technique to improve antibody therapeutic efficacy, safety, and product quality.

This article reviews FDA’s recent efforts to streamline the biosimilar approval process and address quality concerns with the publication of new guidelines that suggest resources to aid in the biosimilar development and characterization process.

In an effort to secure a continuous, sustainable supply of an important vaccine ingredient, Agenus is turning to a plant cell-based cell culture method for production.

The commercialization of cell and gene therapies has become a reality, prompting deeper considerations of logistics, technology, and design for manufacturing facilities.

Simple components help maintain physical integrity throughout a bioprocess setup, and single-use components play a role in ensuring a closed system for aseptic processing.

Single-use systems offer a solution to the challenges inherent in buffer preparation, which can be the cause of bottlenecking in bioprocessing.

Research advances have enabled the application of nanotechnology to drug delivery. What does this technology offer in the way of enhancing therapeutic effect?

This article explores the challenges and potential of next-generation therapeutic antibodies.

Single-use technology is gaining ground in downstream bioprocessing, but challenges stall further adoption.

This article takes a look at current practices for cleaning and sterilizing biomanufacturing equipment used in a multi-product versus single-product setting.

Drug makers continue to explore innovative ways to develop antibody-drug conjugates based on their unique potential to neutralize cancer cells.

A look at the skill sets and training needed to tackle the increasing levels of automation in bioprocessing facilities.

A look at recent investments by contract manufacturers to increase single-use bioreactor capacity.

Downstream process equipment for mAbs manufacturing must be designed to fit technology developments in upstream processes.

As automation in biomanufacturing becomes more important, so does the need to integrate process data.

To ensure the sterility of parenteral biopharmaceutical products, it is necessary to employ certain tools, technologies, and standard operating procedures.

Automation in cell-line development and cell culture is leading to more consistent quality while improving efficiency, and, ultimately, speed to market.

As biologic drugs grow increasingly complex, drug delivery mechanisms such as prefilled syringes are being adapted to meet the challenges.

This article will explore the requirements for media and supplements needed to maintain newer cell lines, such as those based on human cells and fungal cells.

Providing analytical data on the comparison between a biosimilar and the reference product is a primary consideration in the development of biosimilars.

The testing of raw materials is essential as raw material quality determines the outcome of biologic product quality.