Nanoparticles offer the potential for a safer, more effective method of drug delivery to the patient.

Feliza Mirasol is the science editor for BioPharm International.

Nanoparticles offer the potential for a safer, more effective method of drug delivery to the patient.

Bristol Myers Squibb has joined Cellares’ Technology Adoption Partnership program just as Cellares launches operations as an integrated development and manufacturing organization.

Rentschler Biopharma, CGT Catapult, and Refeyn aim to use automated and digital technologies to improve AAV manufacturing for gene therapies.

Danaher intends to acquire Abcam, a provider of life sciences assays and reagents, for $5.7 billion.

FDA has approved a new mAb therapy from Regeneron Pharmaceuticals as well as a higher dose version of Eylea, the company’s eye disease therapeutic.

FDA has halted enrollment in clinical studies for Gilead Sciences’ magrolimab, a biologic treatment in development for acute myeloid leukemia.

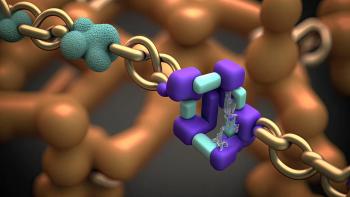

With this agreement, Chiesi Global Rare Diseases will co-develop drug delivery systems with Aliada Therapeutics for large molecule therapeutics that can cross the blood-brain barrier.

The launch of Alpha Teknova’s new manufacturing facility in Hollister, Calif., increases its capacity for custom reagents for life sciences applications.

The completion of three acquisitions of Versanis Bio, Sigilon Therapeutics, and DICE Therapeutics boosts Eli Lilly and Company’s product pipeline in obesity, diabetes, and immunology.

Under the exclusive agreement, Hikma will commercialize products in Rakuten Medical’s pipeline for cancer treatment in the Middle East and North Africa region.

Under a manufacturing agreement, Northway Biotech will develop a manufacturing process for iTolerance’s fusion protein in development for regenerative therapy.

Scale-up strategies for cell culture will require a deep understanding of overall bioprocess workflows.

Advanced analytical tools generate more data in today’s labs than ever before.

Teva Pharmaceuticals and Alvotech will expand their partnership for the development and commercialization of biosimilar candidates.

Janssen has received a positive opinion from the EMA for two novel bispecific antibodies, TALVEY (talquetamab) and TECVAYLI (teclistamab), which the company is developing to treat blood cancer.

MilliporeSigma has invested $25 million to expand its cell culture media production facility in Lenexa, Kan.

Newly launched Crossbow Therapeutics will work to advance a novel class of antibody therapies for treating cancers.

Under a global license agreement, Bristol Myers Squibb and Evotec will advance the development of neurodegeneration pipeline assets.

The proposed spin-off of Sandoz into an independent entity has been approved by Novartis’ board of directors.

Novartis’ acquisition of biotech company DTx Pharma boosts its neuroscience pipeline and expands its capabilities in RNA-based therapeutics.

German manufacturer metabion is conducting a multi-million euro expansion of its oligonucleotide manufacturing capacity in Munich East.

Exploring new fields can bring novel antibody candidates to the pipeline.

Camena Bioscience has completed $10 million in Series A financing on the back of growing demand for DNA synthesis.

Chime Biologics, Leads Biolabs, and BeiGene have formed a three-way collaboration to advance the development and global manufacturing of Leads Biolabs’ lead mAb candidate, LBL-007.

FDA has approved Roctavian (valoctocogene roxaparvovec-rvox), a gene therapy from BioMarin Pharmaceutical for treating severe hemophilia A in adults.

The choice of expression system requires wise consideration of product complexities.

The new headquarters located in Columbus, Ohio, more than triples Andelyn Biosciences’ footprint to meet growing demand for CGT services.

PIF has established Lifera, a new manufacturing entity that will manufacture, stockpile, and supply bio/pharmaceuticals both locally and through partnerships.

India’s Enzene Biosciences is investing $50 Million into a new biopharma manufacturing plant in Hopewell, NJ.

Under the €35 million (US$37 million) investment, MilliporeSigma will expand its sites in Glasgow and Stirling, Scotland, to increase biosafety testing for drug development and commercialization.