The innovation of going from stainless-steel bioreactors to fixed-bed bioreactors shows an evolution in upstream optimization.

Feliza Mirasol is the science editor for BioPharm International.

The innovation of going from stainless-steel bioreactors to fixed-bed bioreactors shows an evolution in upstream optimization.

SMB technology in the downstream can facilitate the shift to continuous bioprocessing.

Takeda received approval in Japan for a subcutaneous injection formulation of Entyvio (vedolizumab) for treating ulcerative colitis.

CDMO Exothera and biotech company Remedium are joining forces to scale up the manufacturing process for Remedium’s lead gene therapy candidate for treating osteoarthritis.

Takeda plans to build a new facility in Osaka, Japan, for the manufacture of plasma-derived therapies.

Under a new partnership, Invitae and Deerfield Management will harness genetic and clinical testing data from patients to discover potential novel therapeutics for treating rare diseases.

Sanofi intends to cut its US list price for Lantus (insulin glargine injection) by 78% and cap out-of-pocket costs at $35 for all patients with commercial insurance.

BioNTech will receive an exclusive worldwide license from OncoC4 to develop and commercialize its anti-CTLA-4 mAb candidate for solid tumor indications.

Sartorius BIA Separations and Teknova will collaborate to combine their technologies in an effort to streamline the downstream purification process.

Samsung Biologics plans to invest more than ₩1.9 trillion (US$1.5 billion) in the new Incheon, South Korea, facility, which will hold a manufacturing capacity of 180,000 L.

Sandoz, a Novartis division, is expected to invest at least $400 million to build a new biologics manufacturing facility in Lendava, Slovenia, to support growing demand for biosimilars.

Under a technology licensing agreement with Bhami Research Laboratory, Catalent intends to develop formulations that will allow for the delivery of high-concentration biologics subcutaneously.

The collaboration between Genuv and Celltrion will utilize Genuv's proprietary mouse platform for antibody discovery.

A slew of late-stage clinical trials is expected to push new regenerative medicines onto the market in the next few years.

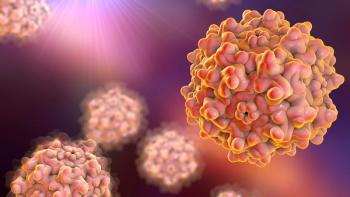

Improvement in viral vector yield has become integral to new cell and gene therapy product development.

Single-use systems hold key benefits for biomanufacturers, despite certain limitations.

Biologic drug development requires relevant bioassays to measure and help predict cellular response.

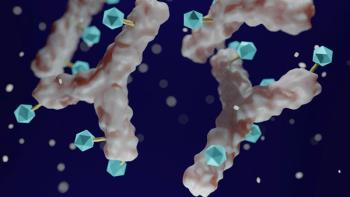

Deeper biological understanding and technology innovations have improved the fate of ADC development.

Learning from early market failures, the biopharma industry has worked to improve the fate of antibody drug conjugates.

Using a predictive modeling approach can help tighten up operator control over bioprocessing, which in turn can increase bioreactor output.

The industry revisits the pros and cons of microbial fermentation at scale for biotherapeutics.

A simplified downstream process can save time and costs but requires enabling technologies.

The growth of the biopharmaceuticals market is feeding back into economies and, in part, is driving the boom in life sciences and biotech ecosystems.

An early drug candidate screening strategy should incorporate clear targets to lessen late-stage failure.

The projected growth in the biosimilars market will require increased bulk mAb manufacturing.

A predictive modeling approach can offer tighter process control, which can optimize bioreactor output.

Preclinical testing is better able to evaluate complex drug candidates thanks to innovations in animal model approaches.

The growth in demand of viral-vector-based gene therapies drives continuous efforts to improve viral vector manufacturing.

The recent approvals of bispecific antibodies have opened the gate for the further development of these complex molecules.

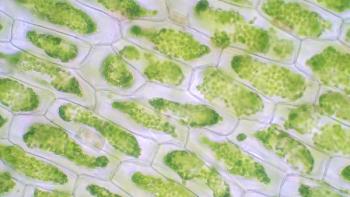

Industry adoption of plant-made biologics remains slow, but plant-based technology gains an advantage by mainstream exposure.