The complexity of newer biotherapeutic molecules calls for alternative drug delivery strategies.

Feliza Mirasol is the science editor for BioPharm International.

The complexity of newer biotherapeutic molecules calls for alternative drug delivery strategies.

Large-scale single-use bioreactors prove successful as limits are tested.

SUB bioreactor performance has had seen its limits and successes.

Establishing a data management strategy in-lab is a first step in generating successful analytical studies.

Establishing bioassay studies for biosimilar development is important for supporting regulatory filings.

Advancements in bioprocessing technologies test microbial fermentation adaptability.

Automation is one asset that benefits cell harvesting by cutting out laborious manual steps and minimizing contamination.

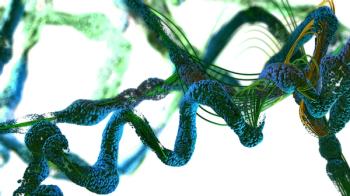

The ever-increasing complexity of biotherapeutic molecules presents unique analytical challenges for developers.

New biologic modalities, such as cell and gene therapies, pose increasing difficulties in viral clearance testing methods.

The emergence of new biotherapeutics is both the driver and result of innovative drug development technologies.

Cell-free expression is promising in preclinical applications, but still presents challenges to scale up for commercial production.

Recent innovations in chromatography resins offer promising advantage in downstream bioprocessing.

Digitalization of bioprocessing operations, equipment, and facilities can improve workflow and output, but maintaining data integrity is a concern.

The expected growth of the global bio/pharmaceutical market is pushing for the continued evolution of the CDMO arena.

Demand for recombinant microorganism-based cell culture supplements is rising on the back of lower contamination risk.

The innovation of single-use technologies is applicable early on in the manufacturing process.

The adoption of single-use technologies in fluid-handling systems helps streamline downstream bioprocessing operations.

Dynamic light scattering presents a good analytical technique for testing protein stability.

FDA’s newly proposed draft guidance will support IND filings of antisense oligonucleotides, a new class of drugs.

A growing pipeline of gene therapy candidates aimed at treating neurodegenerative diseases has prompted new guidance.

Overcoming time and cost constraints can help enable seed train intensification efforts to maximize product yield.

While manufacturing increases have been implemented for vials and syringes, meeting future market needs remains unpredictable.

CDMOs address the unique challenges of liquid and lyophilized forms as well as preparing for the large capacity needed for COVID-19 vaccines.

Cell-culture optimization may see benefits from a synthetic biology-based approach that improves product titer, quality, and time.

Establishing an automated inline dilution system can potentially ease bottlenecking delays resulting from higher upstream yields.

Viral clearance processes and guidance must evolve along with newer biotherapeutic modalities.

Scaling needs for potential COVID-19 vaccines depend not only on capacity, but also on supply chain challenges and technological hurdles.

The shift to single-use technologies is driving the need for innovation in PAT-friendly sensor technologies.

Complex manufacturing processes pose challenges for final product inspection needed to ensure product integrity at commercial launch.

Early detection and more sensitive methods of detecting adventitious agents are becoming increasingly critical in bioprocessing.