Connected, integrated bioprocessing enterprises with greater data analytics capabilities are coming.

Connected, integrated bioprocessing enterprises with greater data analytics capabilities are coming.

Creativity and collaboration are required to overcome complex method development challenges.

Honeywell’s project team has remotely and efficiently migrated Richter Gedeon’s process control system with limited onsite staffing and resources.

The collaboration addresses the need for risk mitigation plans in cell therapies.

Sanofi’s Digitally Enabled Integrated Continuous Biomanufacturing Facility in Framingham, MA was named the Overall Award winner at the ISPE virtual annual meeting.

PAT advances are enabling improved process understanding, process control, and error prevention.

The shift to single-use technologies is driving the need for innovation in PAT-friendly sensor technologies.

Edge-AI technology will enable Industry 4.0 automation in pharmaceutical manufacturing.

Honeywell Forge Cybersecurity Suite’s improved industrial-grade remote access and added protection and risk monitoring aids remote operations.

Automated sampling systems and integration of PAT are overcoming some of the roadblocks to increased automation of biopharmaceutical manufacturing processes.

Ori Biotech is partnering with manufacturers and materials suppliers to develop an automated system for cell and gene therapy manufacturing.

MilliporeSigma’s Bio4C Software Suite combines process control, analytics, and plant-level automation.

Enhancements to Augury’s AI-based machine health platform include new capabilities and collaboration tools for personnel working remotely.

Ensuring the quality of data in process monitoring and control systems starts in process development phases.

Sartorius and the German Research Center for Artificial Intelligence have established a research laboratory for AI in the biopharmaceutical industry.

In batch production, efficient exception management means reducing the time required to identify, review, and resolve process exceptions. Incorporating review by exception functionality within manufacturing execution system (MES) software can streamline biopharmaceutical product release.

Bob Lenich, Emerson's business director for global life sciences, shares insights on where biopharma modeling is now, and where it is heading in the near future.

Modeling is being used for everything from yield improvement to facility design, but new initiatives plan to broaden its reach, both upstream and downstream.

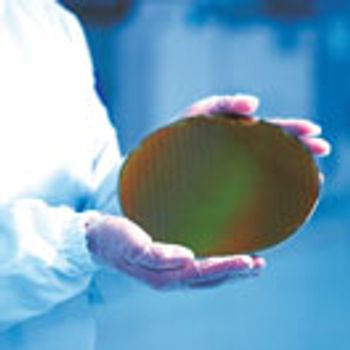

Applying lessons of raw materials’ characterization and supply-chain control from the semiconductor industry allow more rigorous control of the biopharmaceutical manufacturing process.

Cloudleaf's Digital Visibility Platform can track which track location and additional environmental information, such as temperature, vibration, and shock, of sensors placed on raw material containers.

A collaboration between Insilico Biotechnology and IFAT aims to develop a manufacturing, planning, and control system for the production of monoclonal antibodies.

Successful process intensification with inline dilution requires effective monitoring and control.

Now that the first genetically modified cell therapies are being manufactured, the industry must move beyond “whatever works” to meet growing demand.

NIIMBL announced it is partnering with FDA through the University of Delaware to improve biopharmaceutical manufacturing.