The evolution of cell-culture technology is driving the need for improvements in modeling solutions.

The evolution of cell-culture technology is driving the need for improvements in modeling solutions.

The company has launched new services for mammalian cell bank manufacturing under GMP conditions.

The $10-million investment will include a 500-L single-use perfusion bioreactor and seven patented downstream processing units.

Solentim and ATUM have announced a technology collaboration agreement that will focus on the creation of an efficient cell line development solution for biotherapeutic drug developers.

Agenus will leverage Selexis’ SUREtechnology Platform to progress Agenus’ portfolio of next-generation antibody programs.

This research proposes a method for separating and purifying tissue-type plasminogen activator from a fungal cell source.

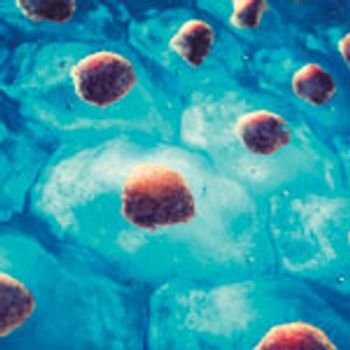

This article will explore the requirements for media and supplements needed to maintain newer cell lines, such as those based on human cells and fungal cells.

The company will collaborate with GlycoBac to offer an insect cell line for the development of viral vaccines and gene therapies.

Catalent Biologics will adopt Berkeley Lights’ Beacon optofluidic platform for its cell-line development workflow.

The new platform is expected to speed up cell line development.

Under this agreement, the companies will develop in parallel an antibody drug candidate and cell lines for other potential candidates.

The study suggests that circumventing evolution in cell factories can enable the commercialization of new biobased chemicals to large-scale.

Gilead Sciences will acquire Cell Design Labs to further cell-therapy research and development efforts.

The companies will collaborate to develop and manufacture Grid’s lead therapeutic candidate for the treatment of solid tumors.

ABEC, an equipment and engineering company, will provide a custom-made, single-use bioreactor to custom manufacturing firm, Emergent, for its Maryland manufacturing facility.

The company announced plans to expand its viral vector process development facilities in the United States and its cleanroom facilities in the Netherlands for vector-based products.

The companies have entered into a strategic collaboration to establish a new cell therapy and regenerative medicine manufacturing platform, which includes a new manufacturing facility in Belgium.

Under an agreement, ProBioGen will develop a stable cell-line for and manufacture an anti-cancer antibody for Chiome using its proprietary cancer cell-killing technology.

Detecting viral contaminants in biologic-based medicines-and identifying their source-requires a holistic testing approach.

Traditional planar culture formats are being superceded by microcarriers for large-scale cell therapy manufacturing.

Consider automation early in the rollout of clinical translation and scale up of clinical-trial protocols.

FDA noted in a recent inspection that US Stem Cell Clinic was processing and administering stem cell treatments that were neither reviewed nor approved by the agency.

Pfizer will invest $100 million to expand its manufacturing facilities in Sanford, North Carolina.

Media manufacturers are focused on reducing risk, improving quality and consistency, and managing costs.

Perfusion processes can attractive for biologics drug manufacturing; however, obstacles remain.