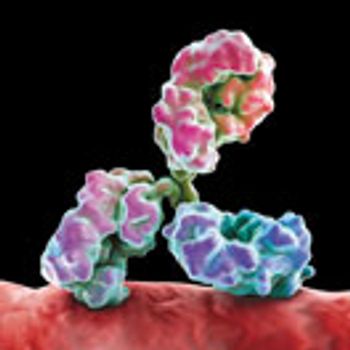

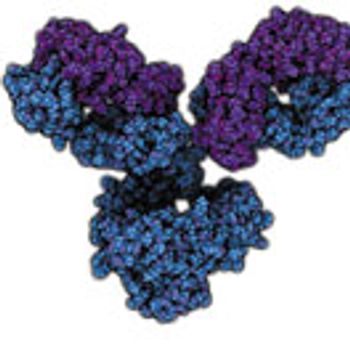

Although Protein A remains a top technology for monoclonal antibody purification, the industry continues to look for new approaches to improve conventional capture chromatography.

Although Protein A remains a top technology for monoclonal antibody purification, the industry continues to look for new approaches to improve conventional capture chromatography.

A multi-pronged approach to raw materials testing can help mitigate the risk of future contamination events.

Pump systems must be designed to meet the needs of specific processes, including preventing cross-contamination and damage due to shear forces.

To prevent failure during lengthy use, tube life should be monitored and a preventive maintenance program enacted.

Despite limitations, mass spec is having an impact on biologic drug development and manufacturing.

Reducing regulatory roadblocks requires more than the stroke of a pen.

Extraction studies demonstrate approaches for evaluating single-use bio-pharmaceutical manufacturing materials.

Susan Schniepp, distinguished fellow at Regulatory Compliance Associates, discusses how to ensure sterility when manufacturing small-scale parenteral batches.

User fee reauthorization is crucial to implementing the Cures Act and refining the approval process.

The outlook for the CMO and CDMO industry may be affected by ever-changing politics.

The objective of this study was to assess the impact of manufacturing-scale, freeze-thaw conditions on aggregation and subvisible particle formation of a monoclonal antibody solution (mAb-A; IgG1) using a small-scale model.

Longer packouts are becoming the rule, as logistics service providers and sponsors gain experience planning logistics for clinical trials involving cell and gene therapies.

Click the title above to open the BioPharm International February 2017 issue in an interactive PDF format.