This article is the third and final in a series designed to offer leaders and managers at all levels in the industry a road map to excellence in human performance and human error prevention.

This article is the third and final in a series designed to offer leaders and managers at all levels in the industry a road map to excellence in human performance and human error prevention.

Chinese healthcare reforms may be a double-edged sword for foreign companies.

As the pharmacovigilance infrastructure becomes more entrenched in Europe, drug manufacturers are beginning to feel the burden of its high cost.

Annual study shows geographic proximity not a factor in CMO selection.

FDA demands accurate manufacturing and test information to ensure product quality.

Careful selection of downstream processing conditions is a must.

Vial adapters can reduce variation of volume withdrawn from injectable drug vials.

A well-constructed quality agreement can be an important tool to enable effective collaboration between owner and CMO.

Industry associations play a strong role in helping the pharmaceutical industry meet challenges.

Developing and maintaining a current master plan for cleaning in multi-product facilities are crucial.

Program review can help quality risk management live up to the promise of ICH Q9.

Experts discuss the future of modular manufacturing and the challenges that biopharma manufacturers face in facility design

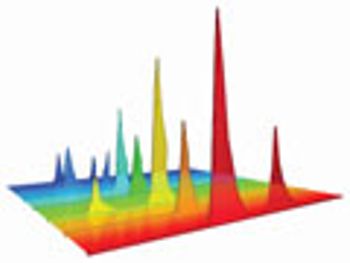

Design space generation is encouraged in new product development.

Click the title above to open the BioPharm International September 2014 issue in an interactive PDF format.