In the big pharma world, drugstore aisle space is every bit as important as Times Square is to New York real estate developers. And few pharma giants fill that space as well as GlaxoSmithKline.

In the big pharma world, drugstore aisle space is every bit as important as Times Square is to New York real estate developers. And few pharma giants fill that space as well as GlaxoSmithKline.

In the rush to save money, the consequences of potential problems often are ignored.

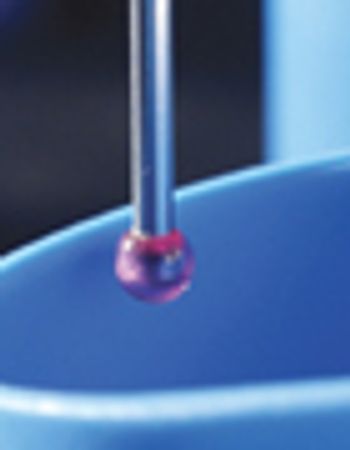

Increased resin stability can extend the number of cleaning cycles that can be performed in situ.

The number of biotechnology-based human therapeutic products in the late-stage pipeline, and the average cost to commercialize a biotech product, have steadily increased. This has required biotech companies to use economic analysis as a tool during process development and for making decisions about process design. Process development efforts now aim to create processes that are economical, as well as optimal and robust.

FDA is working more closely with foreign regulators to keep abreast of drug and vaccine quality issues in their regions.

If a company wants to reduce costs, it should consider outsourcing some manufacturing and analytical testing to low-cost sites.

Whether it's for manufacturing drugs, characterizing cell substrates, or regulating new technology, quality systems provide a needed framework.

This article shows how Probabilistic Tolerance Intervals of the form, "We are 99% confident that 99% of the measurements will fall within the calculated tolerance limits" can be used to set acceptance limits using production data that are approximately Normally distributed. If the production measurements are concentrations of residual compounds that are present in very low concentrations, it may be appropriate to set acceptance limits by fitting a Poisson or an Exponential Distribution.

In the US, the patent term is 20 years from the filing date . . . commercial product may lose patent protection just as sales are ramping up.