Low-pressure process chromatography could not have developed without immense efforts to resolve scale-up issues in both column design and matrix stability.

Low-pressure process chromatography could not have developed without immense efforts to resolve scale-up issues in both column design and matrix stability.

This article explores the development of process chromatography. Process chromatography was first applied to the removal of low molecular weight solutes from whey by gel filtration about 50 years ago. An analytical method using size exclusion chromatography was scaled up for insulin production in the 1970s, when ion exchange became a viable technology for the same application. Ion exchange was adopted as the industry workhorse as robust resins became available and formed the backbone of chromatographic processing of blood plasma fractionation in alternatives to and extensions of ethanol precipitation.

Synthetic ligand adsorbents can eliminate the potential hazards of animal- and microorganism-sourced ligands, minimizing running, cleaning, and validation costs.

Very significant progress has been made since the mid-1970s when dye ligands were first introduced.

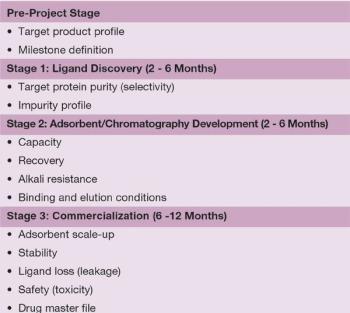

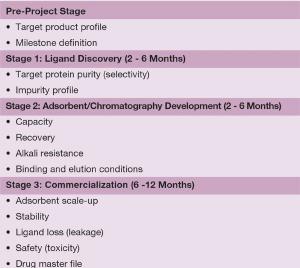

Operational planning and early cost analyses are key to generating optimal, robust, and economical commercial processes.

by John Curling, ProMetic BioSciences Ltd. Immune serum globulin is in high demand, and that demand will only increase. Yet despite product shortages, the complexities involved in creating new manufacturing processes discourage change. The benefits - increased yield, reduced costs, new technologies, and faster throughput - now make identifying the best place in the processing stream to make manufacturing changes a rewrding endeavor. Planned change always trumps losing market share or being forced to change by new regulations.

Published: October 1st 2007 | Updated:

Published: February 2nd 2007 | Updated:

Published: July 1st 2004 | Updated:

Published: August 1st 2004 | Updated:

Published: February 1st 2004 | Updated:

Published: September 15th 2002 | Updated: